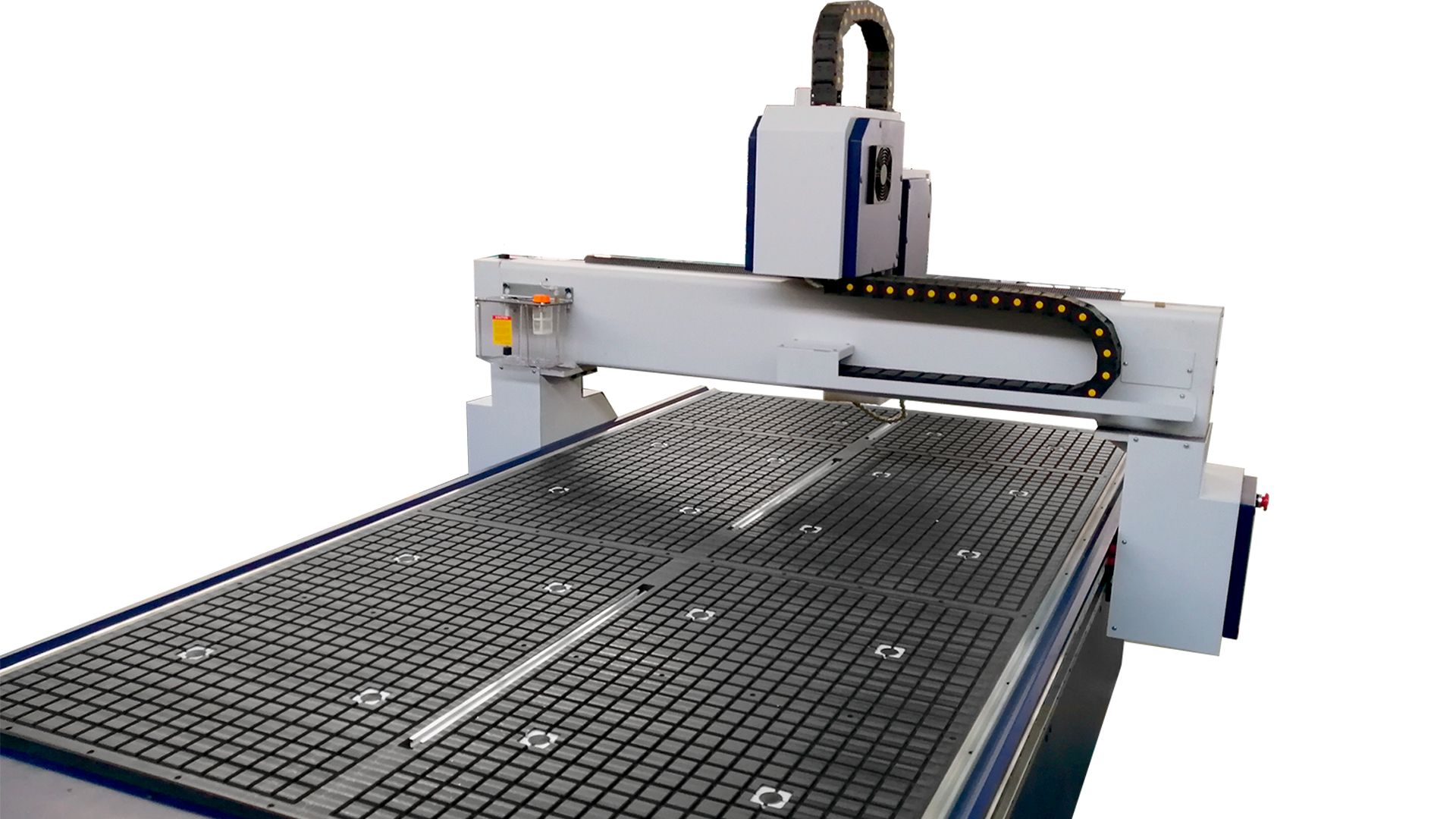

Widcnc R200eCut and milling

The Widcnc R200e is designed to respond effectively to the needs of the demanding professional market. We have developed a precise, robust, reliable and technologically advanced equipment. The robustness and precision of construction, as well as its high precision travel systems, provide unmatched cutting quality.

The Widcnc R200e comes equipped with all the elements needed for a great job, such as “Mist Cooling”, linear rail lubrication, 8 electrically operated vacuum zones, automatic tool sensor, as well as an optional automatic tool change system.

Dimensions (W x L x H): 2750 x 3800 x 2350 mm | Crate: 2280 x 3850 x 2150 mm

Weight: Approx. 1300 kg | Crate: Approx. 1500 kg

Power: Three phase AC 380v 50/60Hz

Maximum Travel Speed: Up to 30m/min

Endless applications

The limit will always be imagination!

Process various materials. Automate processes with the optional automatic tool change.

User-friendly software

User-friendly software with intuitive, simple, and powerful tools suitable for beginners and professionals.

The most reliable CNCs on the market

Widinovations has a complete line of CNCs capable of meeting the most demanding needs in the market. Oscillating knife and optical reading for printed or sensitive materials.

High-quality materials

We guarantee reliable, robust and accurate equipment with unmatched working capacity. Professional and fast response technical service.

Photo gallery

R200e

- Travel speed up to 25 m/min

- Tubular chassis, resistant to corrosion and stress

- Z axis, aluminum with anti-corrosion treatment

- Work area: 2050 x 3050 mm

- Z axis height, up to 200 mm

- X/Y Axis: High precision helical rack and pinion

- Z axis: High precision ball screw

- 25 mm linear guides

- 4.5 kw air cooled spindle

- Stepper motors

- RichAuto A11 DSP Controller

- Vacuum table with 8 zones, electrically operated

- 2 7.5 kw vacuum pumps with filter and safety valve

- 2.2 kw industrial vacuum cleaner

- Automatic lubrication system for linear guides

- “Mist Cooling” tool lubrication and cooling system

- Automatic tool sensor

- Vectric VCarve Pro software

- Network and USB connectivity

R200e ATC

- Travel speed up to 25 m/min

- Tubular chassis, resistant to corrosion and stress

- Z axis, made of aluminum with anti-corrosion treatment

- Work area: 2050 x 3050 mm

- Height Z axis, up to 300 mm

- X/Y axis: High precision helical rack and pinion

- Z axis: High precision ball screw

- 25 mm linear guides

- 6 kw air-cooled spindle

- Automatic tool change with 4 units

- Hybrid servo motors with planetary gearboxes

- Embedded computer

- Vacuum table with 8 zones, electrically activated

- 2 7.5 kw vacuum pumps with filter and safety valve

- 2.2 kw industrial vacuum

- Automatic lubrication system for linear guides

- “Mist Cooling” tool lubrication and cooling system

- Automatic tool sensor

- Vectric VCarve Pro software

- Network and USB connectivity